Drive Plant Efficiency, Productivity and Profits.

Maximise your operational performance with our innovative PLC-SCADA solutions

Connect +919811043930

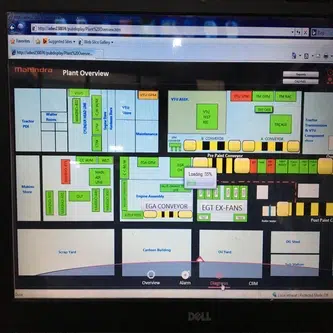

SCADA

PLC PANELS

Projects

In the world of automation, this principle defines our industry—true value goes beyond what can simply be measured. We focus on delivering solutions that make a real difference where it matters most.

At Little Systems, we understand that factory owners need automation solutions that simply work—without the technical headaches. With over 32 years of experience, we deliver reliable, easy-to-use systems that boost productivity and reduce downtime. Our clients trust us to keep their factories running smoothly. Let us handle the complexity so you can focus on growing your business with confidence.

Not everything that can be Counted Counts & Not everything that counts can be counted.

Supervisory Control and Data Acquisition , FAQ?

What is SCADA?

SCADA is a software to collect data from an industrial plant .

Can supervisory control and data acquisition Graphical User Experience and interface be customized ?

scada can be customised screen navigation .trends to improve customer experience .

What does SCADA stand for

it’s full form is supervisory control and data acquisition .

whats difference in SCADA and PLC

PLCS and SCADA both are used in industrial automation tools .PLCS Programmable Logic Controller are a piece of hardware .Supervisory Control and Data Acquisition is scada is a software running on a computer system .

Can Scada replace Data logger ?

Yes SCADA can easily replace paperless data logger .

what is the purchase price of SCADA

The price varies on number of tags in most cases . price also varies with opted software modules.

Does SCADA needs internet for operation ?

no Internet is not must to operate the SCADA .however for web server or web clients internet would be required .

where can SCADA be used?

SCADA can be used in automation of infrastructure process control and control application. it can be used also in utility management like boiler ,chiller ,furnace to process automation , formaldehyde plant. in simple understanding it would get the data from PLC panels running any applications.

Can SCADA be connected to the network of PC ?

yes scada software can be connected to several desktop computers connected over intranet or internet.

What sensors can be connected to it?

All sensors analog or digital signals connected to PLC panels can be connected to SCADA .

Example includes pressure ,temperature ,vibration ,PH level flow or electrical signal parameters like voltage current power factor ,water parameters like density ,PH can be connected to the SCADA software through PLC panels.

What kind of information be stored in SCADA.

All the critical plant parameters ,information related to electric motors running time ,tripping ,breaker tripping ,plant performance and its efficiency ,production can be stored in SCADA software .the information about various electrical ,process parameters can be stored in the database.

what is MQTT

MQTT is the protocol for IIOT communication and SCADA does has MQTT as one of protocols

what does SCADA means .

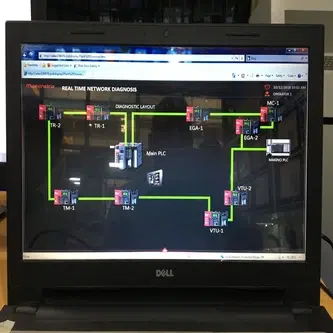

its a software system which is a program running on pc and is connected to controller. scada engineering is done to monitor and analyse the plant data

What kind of PC do i need to run SCADA software

Its preferred to use a workstation PC.

PC with good SSD speed is preferred. faster PC means better or faster brain of software. especially its needed when more of analog signals are used .

What can scada do ?

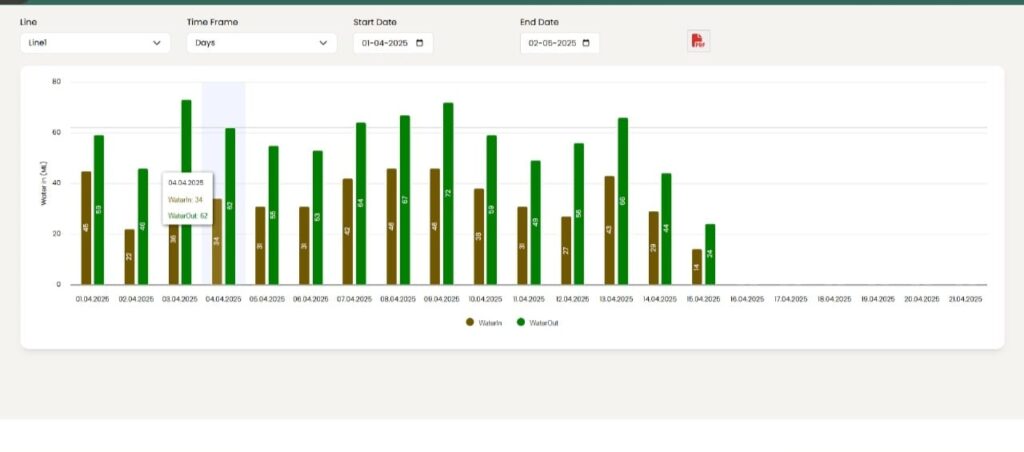

Scada is used in control engineering ,alarm logging .it can log the real time data in data base ,show the real time and historic trends of the data . it can show real time data on the PLANT P& I diagram . it helps to create condition based alarming or time based alarming. it can show the status of pump motors by changing the colour of motor graphic on screen .

It can hold the plant data in database which can be used to improve the plant performance by expert process engineers

Its a good tool in troubleshooting the plant performance.

is there a security in scada

scada has different level of user password to protect the data from unwanted edits or accidental data tempering

Does the user need to renew licence every year,

No usually scada software sells with perpetual licence.

Can it help to connect to Enterprise Resource Planning software

yes it can be connected to enterprise resource planning software like SAP Oracle .these software can poll the scada databse and filter the information .

Is computer hardware important in SCADA software implementation?

Yes IT infrastructure play a vital role usually we prefer to use HP Z series workstation .

What is the ROI of scada software .?

It depends on the cost of products being manufactured in the automation plant . Many times saving in resources can increase profits which are many multiples price of scada

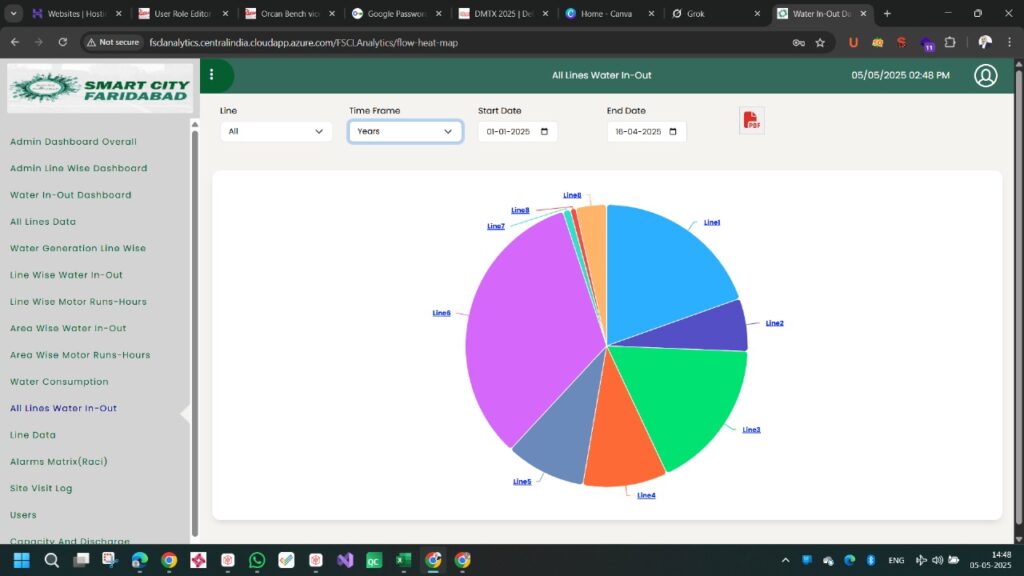

Can SCADA software be used in smart city ?

yes we have used SCADA in smartcity of Faridabad . capturing Water distribution data through the city of faridabad .monitoring of electric motors running hours ,and many other signal from the remote locations . to present the information about water usage ,water wasted etc in the city of Faridabad.

Why xarrow scada?

Xarrow scada in our experience of industrial automation has one of the fastest onboarding & simplified HMI like interface . sms gateway integration data communication includes standard protocols & proprietary protocols . featuring voice alarms which play a audio alarm message in local language resulting in faster response.

Historic Trend with Minimum, maximum & average values are displayed at a glance. it starts almost at the price point of a good hmi .

The size of the xarrow SCADA is about 60MB only .it does not require ,expensive PC with Graphic cards or .NET platform etc.

is the redundancy possible in SCADA

SCADA software can also run as a redundant software . where the data is being captured by two or more systems in realtime .

Mitsubishi Electric SCADA software

mitsubishi electric has been on the forefront of automation projects using PLC,HMI,SERVO . it has full grown SCADA software users in water ,power ,automotive clients , data centers and redundant scada . Genesis 64

Programmable logic controller ,FAQ?

- What does the PLC word stands for , it stands for programmable logic controller.

- How many companies make PLC ?it is a Industrial control Equipment made by over 50 companies popular ones are Siemens ,Mitsubishi,Schenider Rockwell ,Hitachi,Fuji, Omron , ABB etc.

- Does PLC logic incorporates the Ladder logic ? still by and large majority of PLC programs are done in ladder logic however other programming languages are also widely popluar like Structured text ,FBD IEC 61131

- Does Programmable logic controller panels also use Relays ? yes relays are often used to isolate the PLC output from heavy current carrying elements,how ever interlocks of the devices are not made using relays.

- how many kind of programmable logic controllers are there ? small one is referred as Brick type unit where the CPU,Power supply & i/os are intigrated in a single unit ,other controller is referred as RACK type where backplane supports powersupply ,CPU and different cards for inputs ,outputs & special function cards,usually is about 3 times expensivve then the brick type.

- Where is programmable logic controllers are being used ? its used in manufactruing plants where machine or process sequence control and safety is important to product quality ,safety & cost saving

- What is the PLC Cost ? it’s price starts from about 10,000 INR to about 500,000/- and more depending on the configuration.

- Is Programmable logic controller and SCADA same? both systems are used in industrial automation but both are not same,it is more of Control device & scada is more of monitoring software..

- Is programmable logic controller expensive ? In fact plc systems saves lot of time and resources thus increasing profits

- Can programmable logic controller communicate Industrial Data to ERP .Yes it can establish data communications between industrial devices & ERP software.

- Does it needs to be used inside of the panel? yes even though its a industrial device but still it need to be protected from moisture ,Dust etc

- where PLC are used ? PLC are used in the PLC panels .

- are redundant PLC there? yes redundancy in PLC can be planned for various levels like for powerspully redundancy or CPU redundancy next level is digital and analog signal redundancy

When & Where to Start the Automation journey?

to boost your plant productivity .There are many processes in the plant which are being run in manual, semi automatic and automatic ways .

however the scope to improve productivity is often neglected with fear of making huge investments in automations systems, to realize the scope visit Automation scope. for further interactive ideas you can also explore on internet

when electrical energy cost of your manufacturing plant is out of proption to the infrastructure & is going higher Month on month & disturbing the sustainability of your manufacturing plant.Technologies needs to be well embeded in to the plant to make the powersupply quality excellent and cost optimum.

Digital revolution in the Electrical energy ,deploying various industry standard protocols to establist device to device communications and monitor the health of long running equipments.degrading health like of Capacitiors or insulators can make the devices smart.

when unskilled workfoce can lead to risk to the equipment and risk to the workforce needs to be dealt with.Smartphone is the hands of workforce can be used as a personal user interface to manage the alarms, training .The bluetooth in the phone can be used to establish device to device communications.

Eneterprise software like oracle , SAP,Microsoft and others can be connected to indusrtrial networks and Technology like machine learning artifical intelligence can be leaveraged for every day use.

Automation of the machine and process allows you to plan for the preventive maintenace looking into usage data of the machine and various equipments life cycle.User interface can be designed to highlight the preventeive maintenance of upcoming schedule

when data from various equipments like boiler chillers or production equipments needs to be monitored for the wastage.these devices can be connected using IOT where in Industry 4.0 can be implemented with easy to use user interface to pinpoint the inefficiency at the glance.

Manufacturing plantwise data aquisition is becoming the reality

You can aim to meet standards of international society of automation for various automation systems like Alarm philosphy,Standards for Process safety