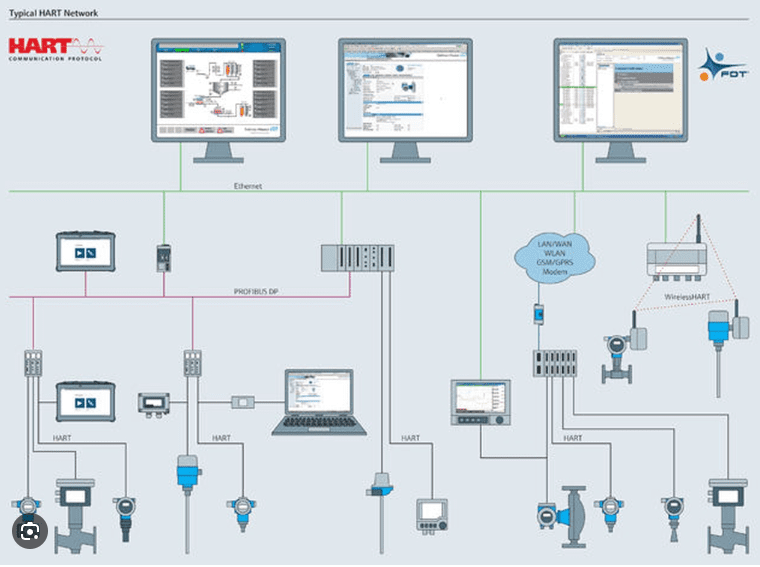

HART protocol for PLC Scada communications in process industry

Are you looking for a communication protocol that can upgrade your existing industrial automation system without the need for additional wiring or infrastructure? Look no further than HART Communication Protocol. it’s very versatile and device specific ,used in process plant instruments.

over one pair of wires it can transmit 4 process parameters of field instruments.

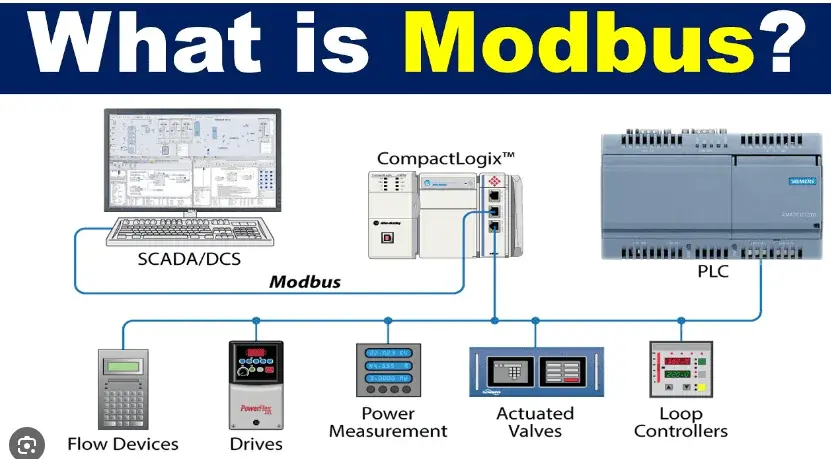

Why use Modbus protocol

Modbus is a widely used serial communication protocol that was developed by Modicon . It is a method used for transmitting information over serial lines between electronic devices, making it an ideal solution for industrial automation applications.

EtherNet/IP (IP = industrial Protocol) is an industrial community protocol that adapts the common business Protocol (CIP) to standard Ethernet.

For beginners, it’s important to understand the advantages of communication protocols in PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) systems. These protocols play a crucial role in enabling communication between different devices and components within an industrial automation system. Here are some key advantages:

1. Interoperability: Communication protocols define a set of rules and standards that ensure devices from different manufacturers can communicate and exchange data seamlessly. This interoperability allows you to select the best devices from various vendors, promoting flexibility and avoiding vendor lock-in.

2. Data Exchange: Communication protocols facilitate the exchange of real-time and historical data between PLCs, SCADA systems, and other industrial devices. This data includes sensor readings, control signals, alarms, status updates, and more. Reliable data exchange ensures efficient monitoring and control of industrial processes.

3. Remote Monitoring and Control: PLCs and SCADA systems often need to communicate over long distances. Communication protocols provide mechanisms for remote monitoring and control, allowing operators and engineers to access and manage industrial processes from centralized locations. This enables efficient management of geographically distributed systems.

4. Security: Industrial automation systems require robust security measures to protect against unauthorized access, data breaches, and other cyber threats. Communication protocols incorporate security features such as encryption, authentication, and data integrity checks, ensuring the confidentiality and integrity of the transmitted data.

5. Scalability: Communication protocols are designed to support scalable systems. As industrial automation systems grow and evolve, protocols provide the flexibility to add new devices, expand the network, and accommodate increased data traffic. This scalability is essential for adapting to changing business needs and accommodating future expansions.

6. Diagnostics and Troubleshooting: Communication protocols often include diagnostic features that assist in troubleshooting and maintenance activities. These features enable efficient identification and resolution of communication issues, reducing downtime and enhancing system reliability.

7. Integration with IT Systems: Communication protocols enable the integration of industrial automation systems with enterprise-level IT systems, such as MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) systems. This integration allows seamless data exchange between shop floor systems and business systems, facilitating better decision-making and optimizing overall operations.

Understanding these advantages will help beginners appreciate the significance of communication protocols in PLC and SCADA systems. They form the backbone of reliable and secure communication, enabling effective control and monitoring of industrial processes.

all in all using industrial protocol, we benefit with exchange of information between devices from different suppliers so as to make industrial network .the befits of each protocols depend on the environment where they are used ,what information is shared whether critical or health based information.