IOT (Internet of Things) to visualize your plant operations

IOT , INDUSTRY 4.0 Technologies can monitor plant health & plant efficiency

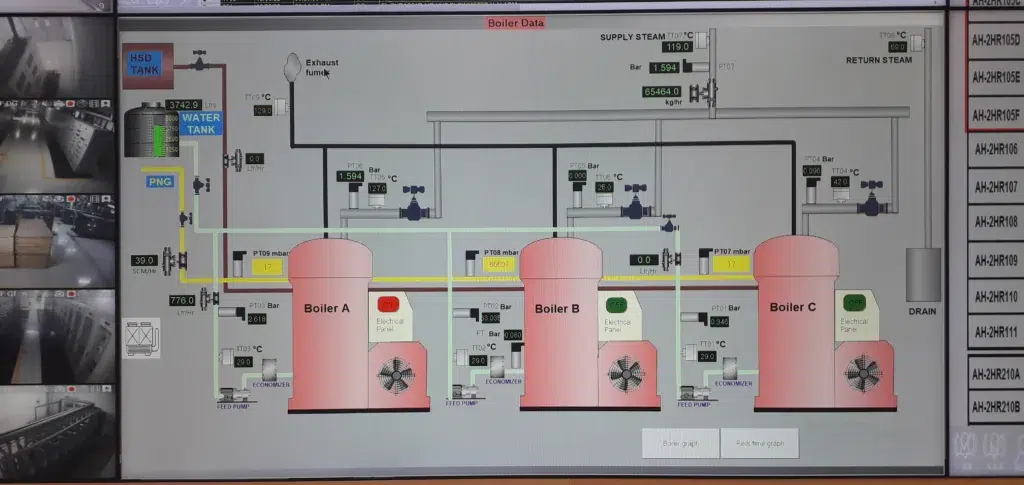

How compressors and boilers can benefit using IOT ?

In a typical plant, all equipment, such as compressors, boilers, or gensets, is running in the utility section. Concurrently with plant operations, plant management is primarily concerned with monitoring plant production, which involves billing and revenue collection.

However, many resources are being wasted or overspent due to equipment running below its peak performance. Many pieces of equipment tend to experience certain degradation in their performance due to ongoing scaling, filter clogging, less lubrication, etc.

Many of the Plant motors, such as paint booths and compressors, tend to have increased or reduced current due to several issues, including bearing problems, misalignment, and excessive air pressure loss caused by unnecessary bends in the pipeline. Such issues can be addressed when all this equipment is part of the condition-based maintenance planning by implementing IoT, taking the health and performance data of these devices to the maintenance server, and monitoring it 24/7 for the KPI.

What is IOT ? (Internet of Things)

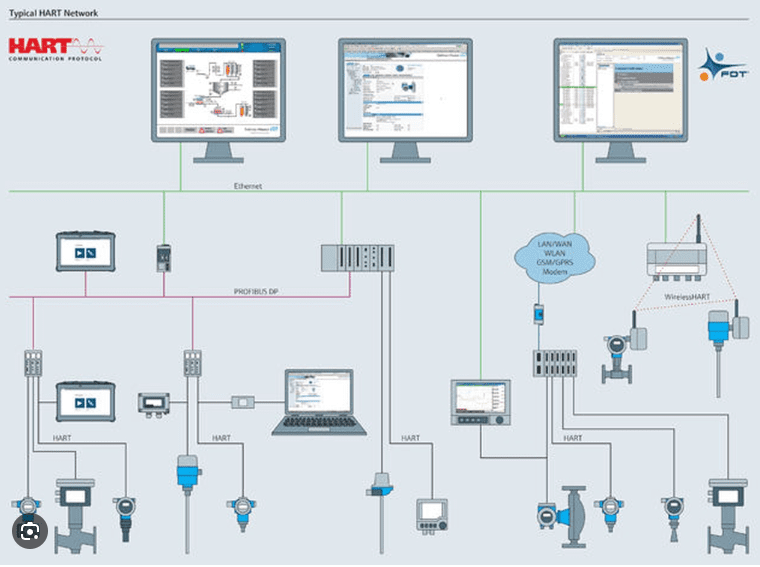

In simple layman’s language it’s when intelligent devices can transfer the data to other devices or the Cloud through a standard wired or wireless network

what are the components of IOT

- Smart Device

- Network

- IOT software

- User Interface

Example Of IOT

Smart city operations involve accessing city infrastructure data for operational performance using a vast area network, and presenting data over the cloud in a customized software interface suitable for the authorities.

Advantages of IOT

Data from different sources can be combined, and many processes can be analyzed for process improvements, etc

Edge computing component for IOT & Industry 4.0

A very versatile & latest for factory automation needs, be it a simple sequence control or Servo motor control using motion module, or communicating with energy meter using Modbus protocol, or SCADA connection using ethernet port

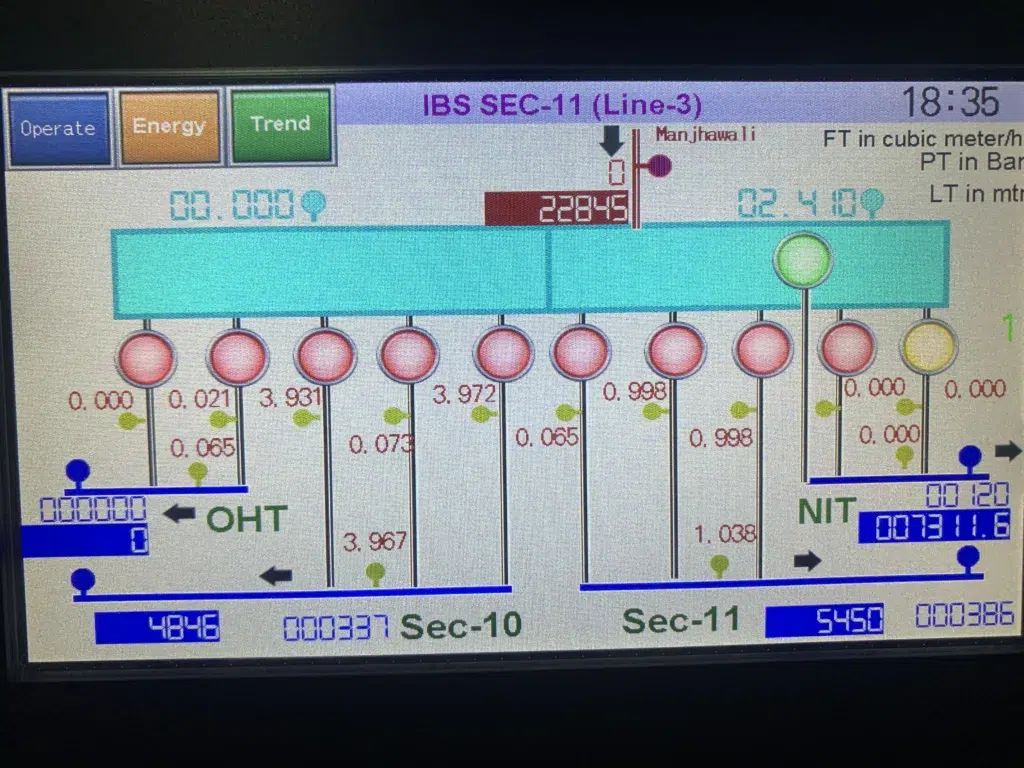

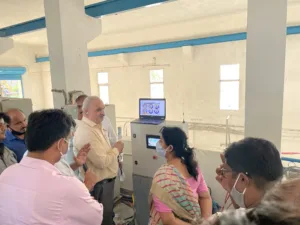

user interface software xarrow SCADA for cloud connectivity

A full-featured SCADA/HMI software running on a Windows system, it supports almost all popular PLC devices and can be used as an OPC server, a Modbus/ModbusTCP slave, or a Bacnet/IP gateway.

xArrow can meet the requirements of single-user applications to complex Client/Server applications with redundancy, and users can use an Android phone to browse the project.

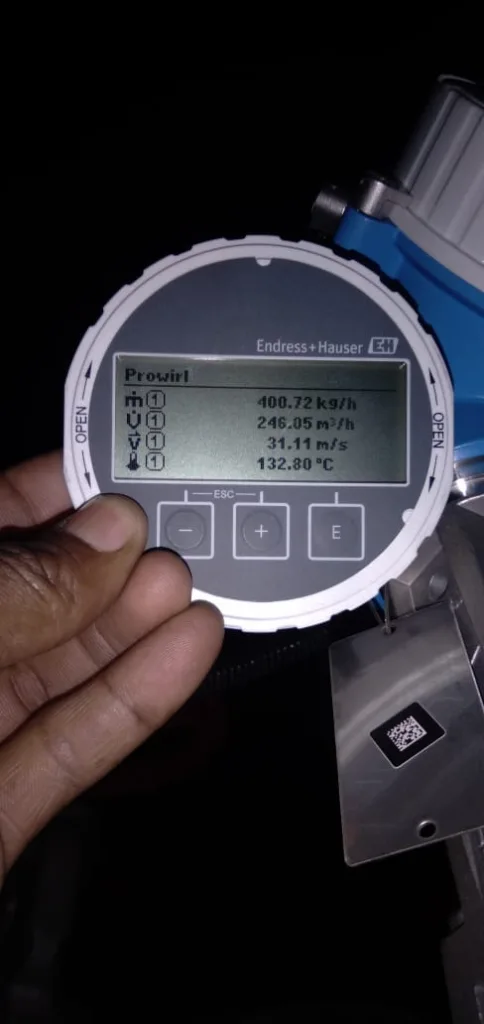

Smart Field Instruments for process interface

For process automation projects, we select, order, supply & commission various field instruments, including vortex flowmeters, Coriolis mass flowmeters, differential pressure transmitters, and pressure transmitters.

Using 4 to 20 mA analog outputs along with HART protocols for easy communication to the controller

Control Panels having plc , vfd & servo drives

We supply control panels for various application that connect the machine to the IOT

Engineering services

Engineering services start at the very beginning of the projects where we try to understand the clients idea of the automaton to eradicate the challenge they are facing be it chiller monitory ,or furnace monitoring or andon on the conveyor line.

Then we discuss and suggest and discuss and present the automation solution from proposal to execution all through our team