monitoring chiller and boiler using sensors, PLC & SCADA.

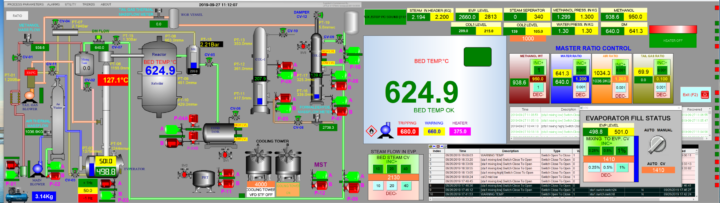

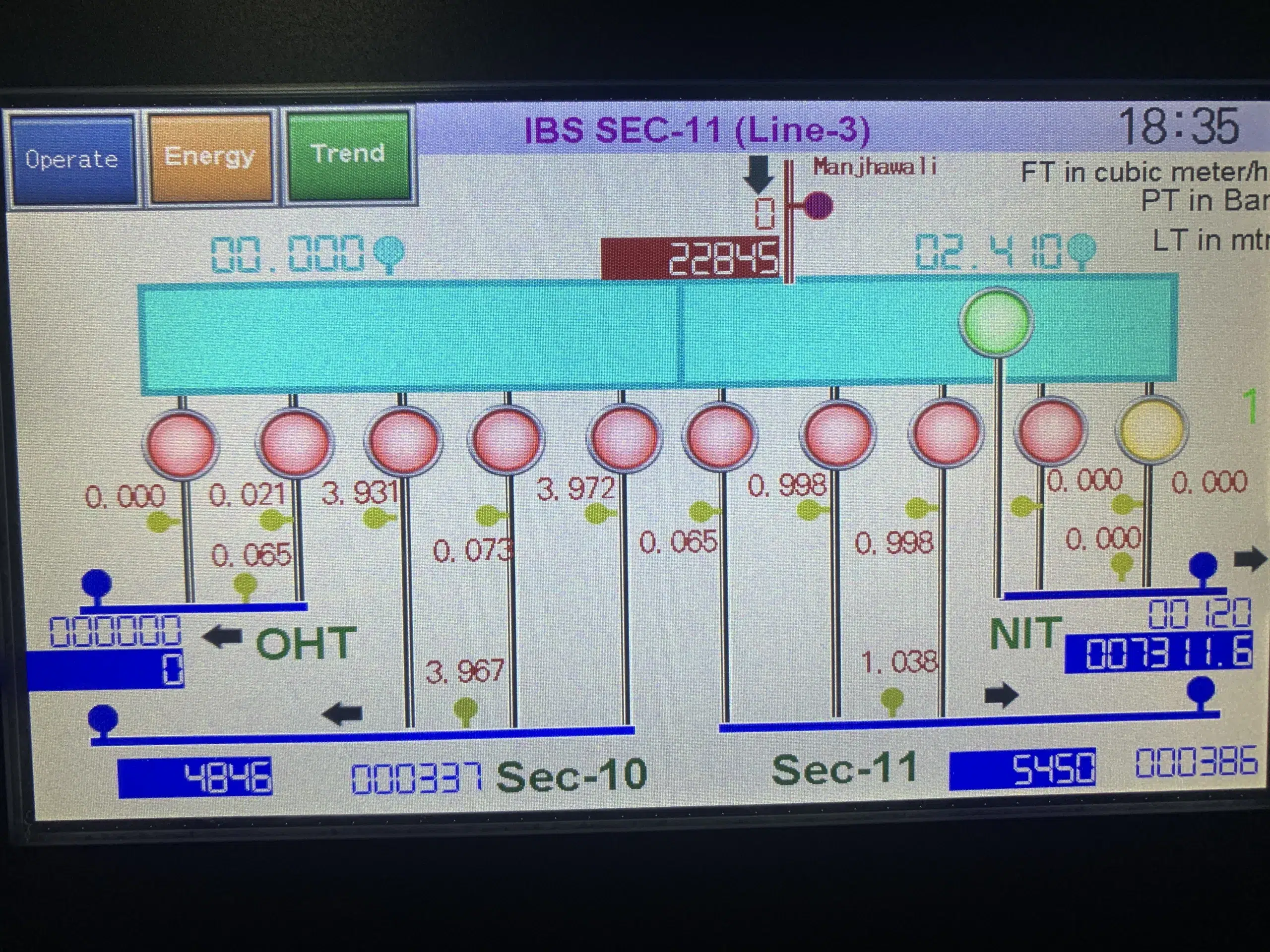

boiler & chiller operations monitoring in SCADA

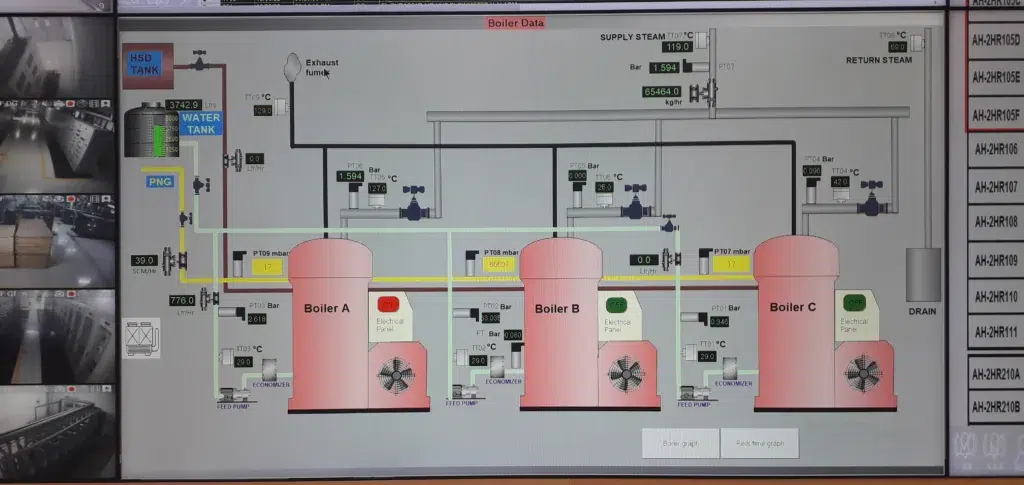

A steam boiler plays a vital role in the manufacturing plants of white goods. The steam at constant temperature and pressure is used in semiconductor fabrication and sterilization. It’s also used in many sanitation and cleaning processes. To increase productivity, the metered water is fed. The fan motor is monitored, and the steam pressure and flow are measured using a flowmeter. PNG consumption is also monitored using a flowmeter. The steam produced is logged using a flowmeter, connected to the analog input of the PLC

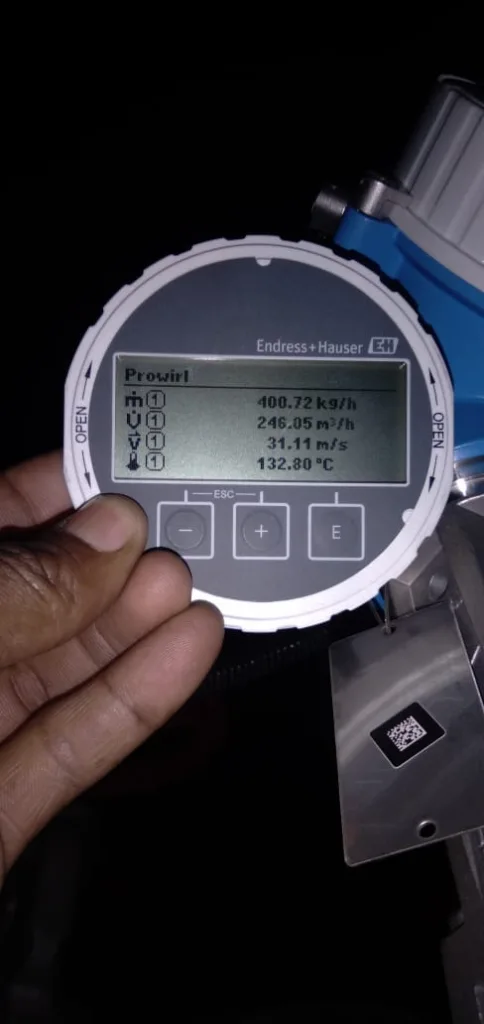

PNG flowmeter to measure and monitor the fuel consumption

PNG fuel was measured using an Endress and Hauser flowmeter.

The fuel consumption to the boilers was monitored and logged on the SCADA through PLC analog inputs

The flow rate of PNG and the totalizer value were logged in the SCADA as a result of PNG consumption against the steam produced.

Chiller performance is being monitored using temperature and pressure sensors.

Chiller monitoring through temperature and pressure for the inward and outward water lines. Thermocouples and pressure transmitters are connected to the PLC via analogue inputs. All the sensors were wired using shielded cables.

PLC panels to connect the field sensor, flowmeters, and data to SCADA

Mitsubishi PLX FX5U with analog inputs is used. One panel connects to the three no-boilers and their sensors.

The lower PLC panel connects to the chillers and their respective sensors.

Both PLCs are connected to the SCADA software. An Ethernet Cat five cable is used to connect the PLC to Xarrow SCADA

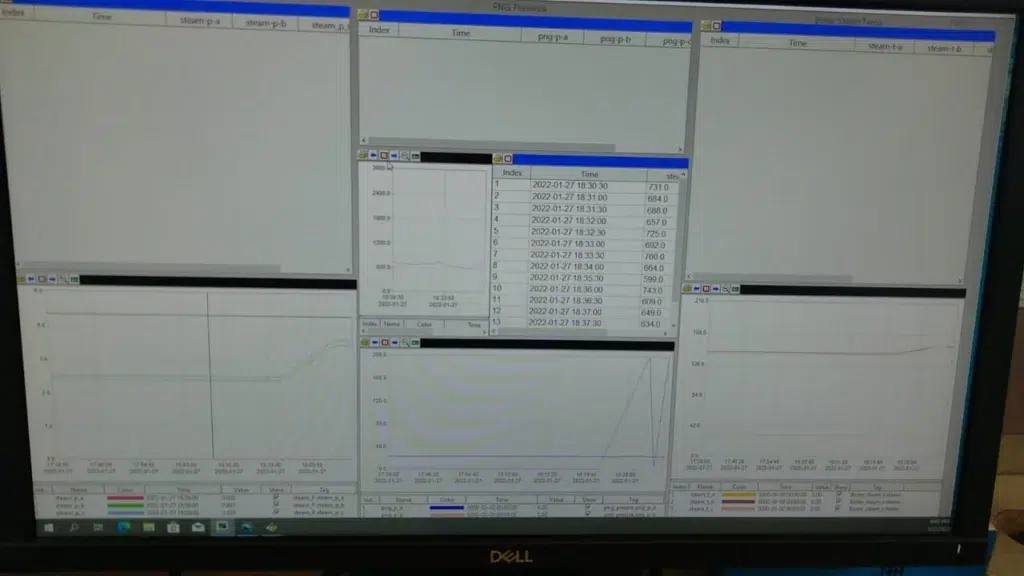

Real-time and historic Trends of Steam PNG fuel, Water in SCADA

Real-time trends of the water consumption, PNG consumption, Steam produced, and Temperature of the steam.

Historic trends of the all parameters are stored for the analysis & records.SCADA does real-time monitoring of all flow, pressure, tand emperature parameters for boilers and chillers on a single pc

Xarrow SCADA was used to run this application at Samsung Electronics’ Noida plant.

want to know more

There is much more to the project than what is mentioned here. For more detailed discussions about the benefits and costs of the project, feel free to reach out to us @ 9811043930.

plcscadaforall

Source PLC SCADA & Automation solutions for Productivity

FX5U PLC of Mitsubishi Electric

IQR PLC of Mitsubishi Electric

GS2107 HMI of Mitsubishi Electric

Chiller monitoring

Boiler Monitoring

Interactive screens