162 sensors’ Real time,Condi tion-Based monitoring using PLC & SCADA

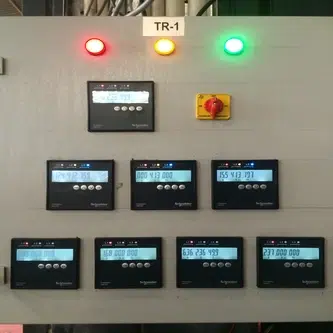

44 pressure, 42 current,48 temperaturetransmittersfrom Radix, and 28 vibration sensors attached to a 10-remote Mitsubishi PLC connected in a network , to monitor in real-time against preset values . All the values alarms logged in SCADA

CBM avoids costly Breakdown Maintenance

The CBM system works to monitor in real-time the critical sensor values, raising alarms before it results in downtime/breakdown maintenance.It’s a monitoring arrangement where plant-wide critical sensors are outlined, and sensors used in IIOT are mounted and connected to the edge-controlled devices ,which can log the data and the data is compared in the PLC against set values predefined in SCADA systems.

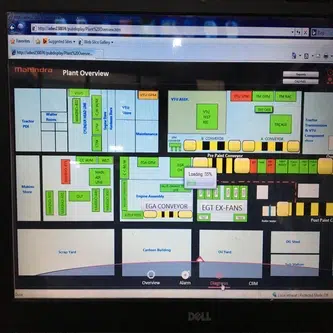

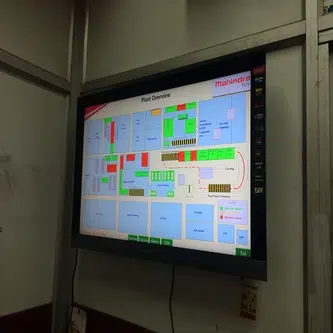

plant-wide monitoring of critical sensors on a single screen of scada

All the status of the plant, including the main conveyor, transmission line, and paint shop, is brought on a single screen of SCADA.

Any abnormality in the plant would be shown on the SCADA screen.TV is placed in the maintenance department.Predictive maintenance is possible.

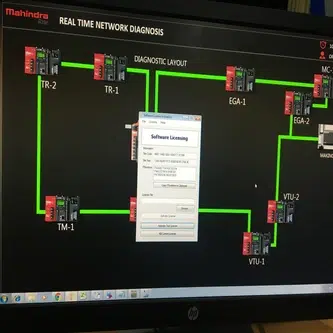

plant-wide PLC & sensor network for Real-Time condition monitoring.

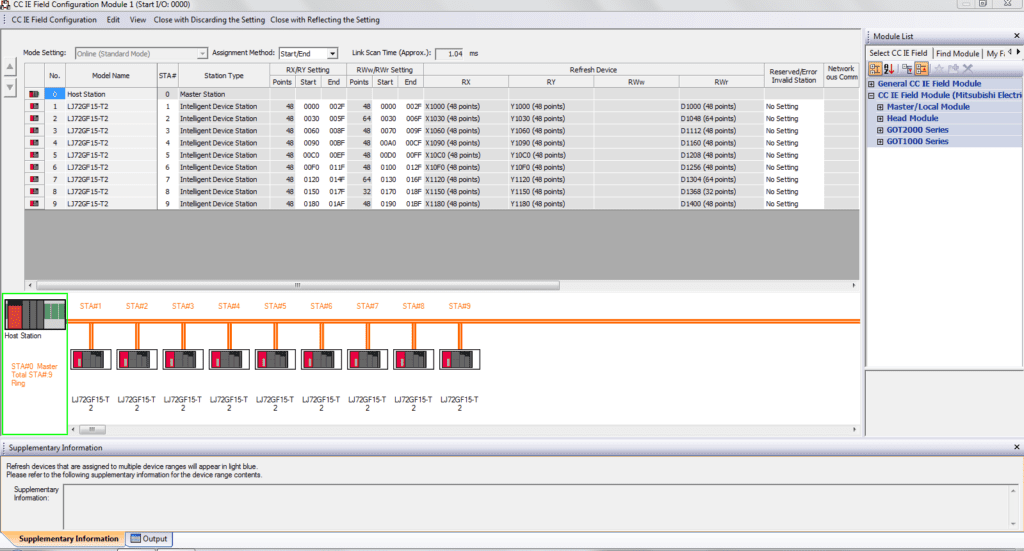

Mitsubishi PLC is used in the plant-wide 10 locations. They capture the digital and field instrument readings continuously. All the PLCs are connected using an Ethernet cable. The main PLC used is the Q series PLC, and the remote nodes are L series PLCs.

All PLCs have analog inputs to monitor Current, Temperature, pressure & vibrations.

Mitsubishi Iconics SCADA ,PC & Monitor the complete environment for CBM

43″ TV used as a SCADA monitor to view the plant wide operations on the big screen. TV connected to a workstation PC running Genesys64.AN HP Z4 series workstation with 16GB RAM isused to run SCADA. Each sensor trend is monitored to evaluate how the value is changing in last few weeks /months to allow prediction of sensor data in future .

Networking of PLC panels

10 PLC panels used throughout the plant in a network using Ethernet wire. All sensors’ signals are connected to analogue inputs. Q series PLC had two Modbus cards and an Ethernet-based card .L series PLC used 9 no.s in remote plc panels.

A series of Mitsubishi L series PLCs and Mitsubishi Qseries PLCs were connected in the wide area network. The PLCs were connected using Ethernet cables. The total length of the network was about 1 km. All the sensors were connected to the 9 PLCs over analogue inputs. Motor current was connected to the PLC using RS-485 Modbus communications. The Q series PLC was connected to SCADA over the Ethernet port for alarm monitoring, trend monitoring & report generation.

The motors, like the blower motor in the paint booth, which is mounted over 50 feet above ground, are monitored for vibration, current, and temperature. These motors cannot be accessed in working condition otherwise.

Pressure drop across the PHE plate-type heat exchanger can provide performance data, which is difficult to monitor otherwise when gauges for these are not humanly feasible to monitor every day, given 30 of them spread throughout the plant.

All this arrangement for CBM is at the suggestion of a Japanese consultant to monitor and improveplant productivity.

This project was very challenging as the customers’ demands evolved with the project execution & the suppliers’, solution & skill set as far as the reporting was concerned was evolved to match the client demand and some extra software modules were used to meet the client’s needs of automatic email posting of the reports .

The timeline of project execution was within 4 months from scratch to the handover.although the challenge for the plant site was high as the team had to lay the wire connect the PLC over 100 meters apart .

all was done successfully leading to the client and team satisfaction.