Benefits of Automation in a Formaldehyde Plant

When it comes to formaldehyde plant operations and performance, the operator’s skills matter, but automation matters as well, as it operates 24/7/365 days.

Automation helps run the plant smoothly at optimum steam pressure, with flows, levels, and working parameters all within 0.2% of the set values.

Raw materials, energy, and plant efficiency are crucial in our automation strategy, utilizing Process PLC to maintain control where it matters.

Our Achievements for Formaldehyde Plant Automation

Mitsubishi IQR Process PLC

Mitsubishi IQR PLC offers unmatched benefits for the process industry, which include a proprietary PID control algorithm that achieves 0.03% control of PID process variables.

Hart Protocol offers the value of four parameters over one pair of wires

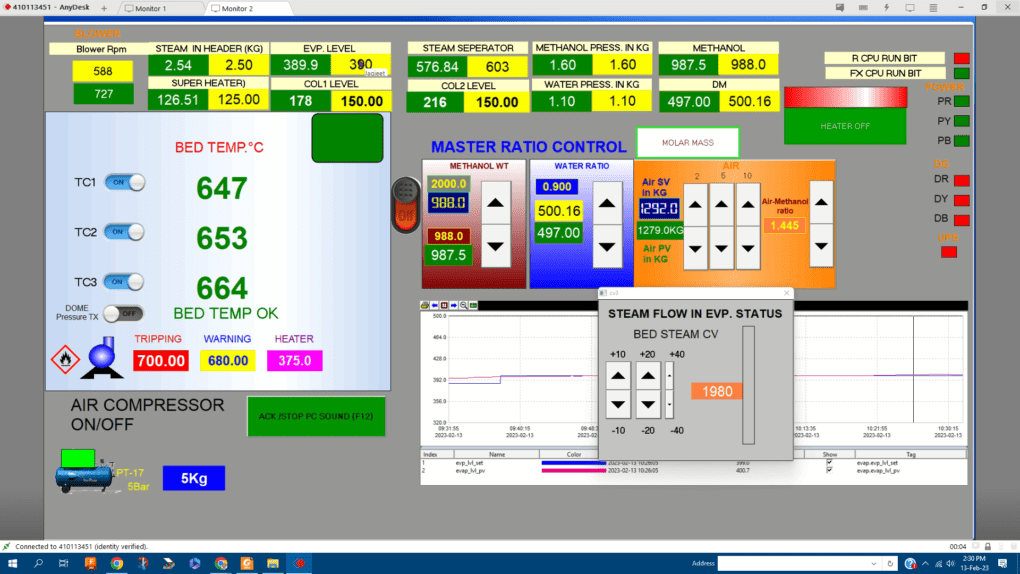

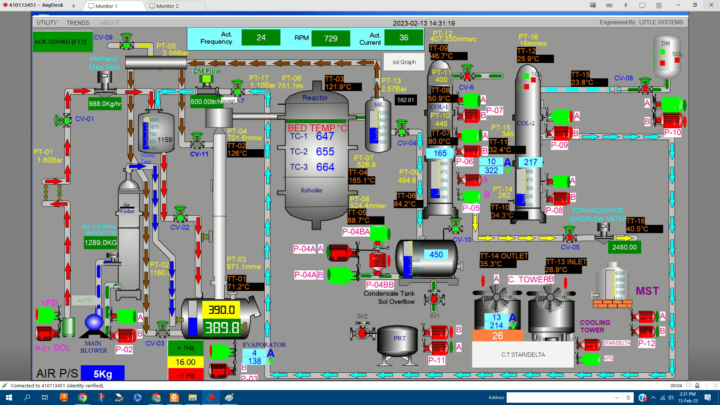

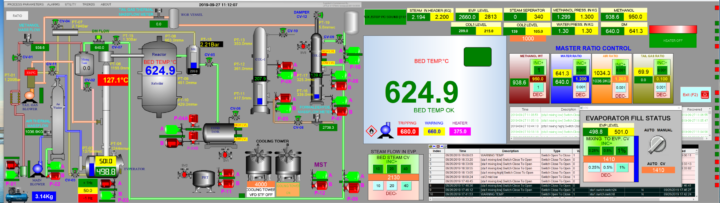

SCADA with Dual Screens

With a P&I diagram displaying parameters & pump status on one screen, and a second screen showing set values, process values, alarm logs, and a reactor bed temperature warning, Plant changes can be made without disturbing the monitoring from the second screen.

We use a Mitsubishi IQR process PLC to efficiently control the PID operations. We utilize a Mitsubishi VFD to dynamically control the motor RPM, thereby regulating the flow & pressure. Modbus communication with the energy meter logs the voltage, current, and power factor onto the SCADA computer.

Plant efficiency reporting

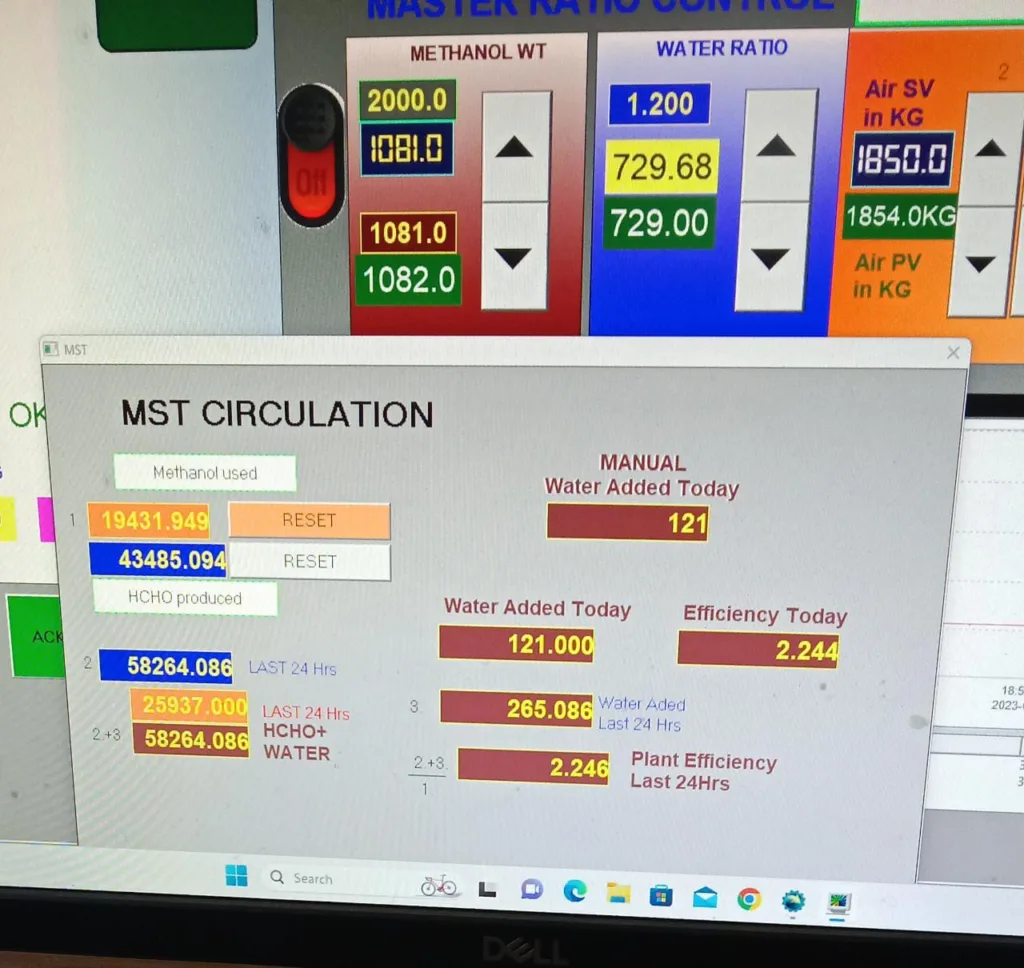

The SCADA computes the plant’s efficiency in real-time. The HART communication protocol is used with a Mitsubishi PLC. It transmits real-time data values from all mass flow meters.

Water added to formaldehyde to maintain strength is also captured using a flowmeter. Plant efficiency is calculated, considering all available data, as shown in the screenshot.

Efficiency data is also logged into the SCADA for daily and monthly comparison. All raw materials data, such as methanol and water consumption, is logged into the database.

MCC panel with integrated VFD and PLC communicating to SCADA.

Form 3B, MCC panel houses all Switchgear, V FD & PLC for the process and motor control

cable alleys, top entry of control and power cables

The critical part of the panels is on the UPS.

Formaldehyde plant operation using SCADA software.

This video shows how we harness the power of SCADA in formaldehyde plant automation.

PLC VFD panel for formaldehyde plant control

How Mitsubishi VFD, IQR Process PLC & FX5U contribute to the effective control in the formaldehyde plant

Mitsubishi IQR PLC is used to control the PID process. FX5u PLC is used to establish MCC switching operations and Modbus communications. Mitsubishi VFDs provide current, voltage, and other related data to SCADA.

SCADA screenshot for plant overview