Furnace monitoring using PLC & SCADA

Annealing Furnace

Forged parts undergo a controlled annealing process. Here, forged components are kept under a certain temperature for a certain time to change their physical /chemical proterties .. The process of annealing increases ductility and decreases hardness, improving the part’s workability.

Benefits of SCADA in annealing furnace.

Furnace SCADA logs: parameters, temperature, soaking time, conveyor speed. Reports of temperature and soaking time improve quality. Reports indicate that the batch was at the correct temperature and time. SCADA does it automatically without operator skill.

The furnace PLC SCADA price starts at INR 1,30,000.

Improves the productivity of the furnace

The Xarrow SCADA helps to control the operational cost of the stove. Product quality improves when the conveyor runs through the recipe. Temperature, soaking time, and conveyor speed are logged.

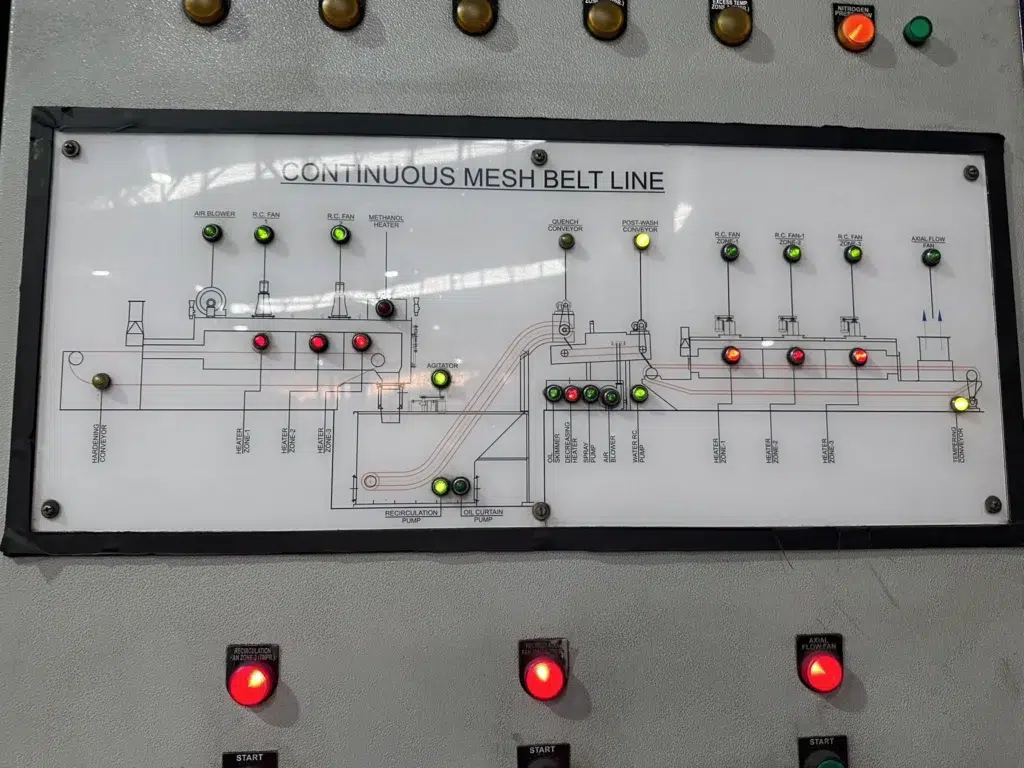

Continuous Mesh belt line furnace monitoring and controlling using PLC and SCADA

This a more complex process . its a four stage furnace . the conveyor speed , temperature all logged . scada helps to run the furnace at best quality.

The report includes the product name, specifications, client, and operator.