Experience Our Projects Expertise

Of Process & Factory Automation

Can just Right products ,make your Application Successful?

Expertise in PLC programming is a core competence.

It’s surprising, but practically true, that the best-known brands and their Products fail if the application is not engineered well to meet the application’s demands.

The knowledge about the products and the demands of user applications must be optimally matched to put the pieces of the puzzle together, which also includes the budget.

It’s more about application engineering, which counts. A good solution is where a good modern, and optimum range of products is selected with application demands in view, to get the desired ROI, balancing the Results & Problems

Project Execution expertise takes more then Product know how & application's know how. Understanding the Intrinsic Environment of shop floor, work flow also goes long way to make it sustainable in long Run. Not just PLC programming.

It’s surprising, but true: even the best-known brands and their products can fail if the application is not appropriately engineered to meet user demands.

To succeed, it’s essential to optimally match knowledge about the products with the specific requirements of user applications, all while considering the budget.

The focus should be on application engineering. A successful solution involves selecting a modern and appropriate range of products that align with application demands, aiming to achieve the desired return on investment (ROI) while balancing results and potential issues. Knowledge about the products and the needs of user applications must be optimally matched to put the pieces of the puzzle together, which also includes the budget.

It’s more about application engineering, which counts. A good solution is one where a modern and optimum range of products is selected with application demands in view, to achieve the desired ROI, balancing the results and problems.

What you get from our Team is their sincerity, loyalty & good engineering expertise, as well as product know-how, which goes unsaid.

- Our automation expertise lies in developing PLC sequence logic for machine tool controls. Working with digital and analogue inputs and outputs, servo control using pulses, and a motion card. We have developed PLC sequential logic for various applications, including greenhouse automation, furnace control, Load cell integration, Energy management, and more complex applications such as formaldehyde plant & process control.

- Modbus, CAN bus, and other protocols are commonly used to communicate with third-party devices, such as a temperature controller, an Energy meter, etc.

- Process Automation Experience involves integrating various process instruments from Pressure, Temperature, flow, level, Coriolis, thermal massflowmeter using analog outputs, to using HART protocols, where four parameters from instruments are communicated to the PLC using just one pair of shielded cable

Project Execution expertise takes more than product knowledge and application knowledge. Understanding the Intrinsic Environment of the shop floor, work culture also goes a long way to making it sustainable in the long Run.

What you get from our Team is their sincerety ,loyality & good engineering expertise and product know how goes unsaid.

What we Do in your plant to make your application successful remains reserved for you, not for your competition .

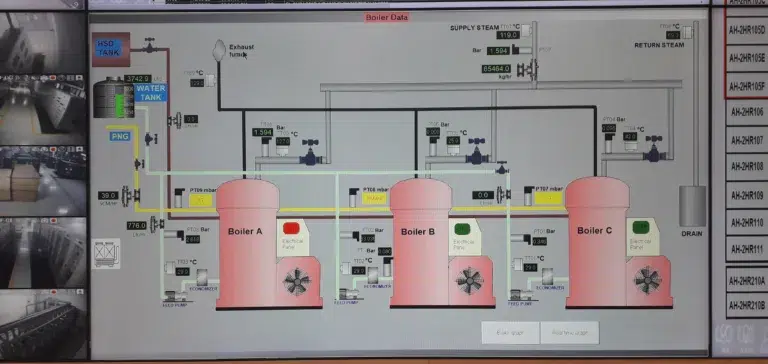

Creating SCADA UX + UI to meet application Demands, much deeper than the customer expects, is our Expertise.

Automation Domain expertise of PLC ,Scada Process automation,VFD panels ,PLC panels & site commissioing.

Our automation expertise lies in developing PLC sequence logic for machine tool controls. Working with digital and analogue inputs and outputs, servo control using pulses, and a motion card. We have developed PLC sequential logic for various applications, including greenhouse automation, Finance control, Load cell integration, Energy management, and more complex applications such as formaldehyde plant & process control.l

Apart from sequence control using Modbus, CAN bus, and other protocols to communicate with third-party devices like a temperature controller, energy meter, etc., communication is established.on

Process Automation Experience involves integrating various process instruments, including pressure, temperature, flow, level, and thermal mass flow meters, using analog outputs. This integration also utilizes HART protocols, which enable the communication of four parameters from instruments to the PLC using just one pair of shielded cables.e

We have tuned the Cascaded PID for flow, level, pressure, and temperature in the range of 0.03% of SV, being monitored in SCADA every 5 seconds for 24 hours of usage.

As engineers, we understand the challenges our clients face in optimizing their processes and increasing efficiency. We take the time to analyze their pain points and identify areas where improvements can be made. We then work closely with our clients to suggest solutions that are tailored to their specific needs and budget.

We have a Team of Experienced Engineers who have worked in the field of automation, including hydraulics, pneumatics, and the process industry, which involves PID controls, mass flow meters, and other related technologies.

Our engineers have worked extensively in the field of PLC for machine tools and process applications

We are a team comprising Experienced Engineers with a total combined Automation experience of over 90 years.

- Designing the PLC SCADA control Panels is an activity that requires the satisfaction of four stakeholders: the fabricator, consultants, site conditions, and our design team.

- Panel wiring is mainly done according to design, but customized panels present some assembly and wiring challenges.

- Panel assembly and commissioning, most of the work is done at our works, but completion happens at the site.

- Site commissioning of control panels and field instruments is one of the most laborious tasks, as most sites offer different challenges.

- Accounts to keep commercial invoicing in line with supplies and solution deliveries

- Logistics personnel are responsible for ensuring that all designated deliveries are on schedule during dispatch.

- Understand the client’s pain points and opportunities to improve, and suggest a solution that suits their budget, offering a reliable solution.

- PLC Sequence logic for machine tools controls involving digital, analogue logics & servo controls

- Process Automation involving PID control for the flow, level, pressure, using process instruments like mass flow meters, Differential pressure transmitters, etc

- SCADA control for process monitoring, controls, reporting, alarming & analytics