Modbus Protocol Explained

Modbus benefits & tradeoffs

Modbus in Plain words

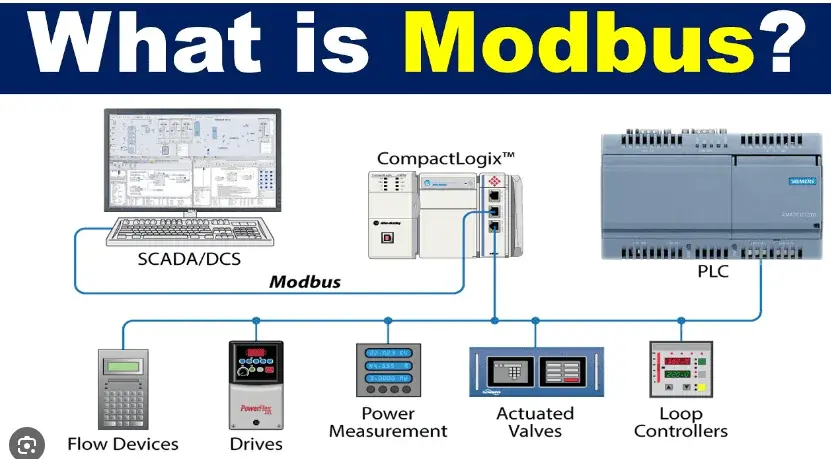

Modbus is a industrial PLC to devices communications protocol where in PLC can read or Write data words in the third party devices like Temperature controller or Energy meter

Modbus Protocol Explained in detail

It is a widely used serial communication protocol slow but reliable.

Maximum of 32 devices can be connected to plc using this protocol and maximum distance can be 100meters .the maximum speed and distance varies as per the no of connected devices on the network.devices from different manufacturers can be connected but they have to have same communication settings like no of stop bits, parity,communication speed etc.

It was developed by Modicon in 1979 for use with its programmable logic controllers (PLCs).

It is a method used for transmitting information over serial lines between electronic devices, making it an ideal solution for industrial automation applications.

In a standard network, there is one client and up to 247 servers, each with a unique server address from 1 to 247. The client requests information from the servers, and the servers supply the requested information. The client can also write information to the servers, enabling bidirectional communication between devices.

It is a simple and robust protocol that has been widely adopted in industrial automation applications. It is easy to implement and can be used with a wide range of industrial devices, including sensors, actuators, and programmable logic controllers.

At our company, we offer these solutions that can help you upgrade your industrial automation system and improve overall productivity. theses devices are reliable, easy to use, and can be integrated into your existing system with ease. Contact us today to learn more about our its solutions and how they can benefit your operations. Modicon programmable controllers are designed to communicate with each other and with other devices over a variety of networks, making them highly versatile and adaptable to a wide range of industrial automation applications. Supported networks include the Modicon Modbus and its Plus industrial networks, as well as standard networks such as MAP and Ethernet.

Access to these networks is provided through built-in ports in the controllers, as well as through network adapters, option modules, and gateways that are available from Modicon. For original equipment manufacturers, Modicon ModConnect ‘partner’ programs are available for closely integrating networks like Modbus Plus into proprietary product designs.

The common language used by all Modicon controllers is this protocol. This protocol defines a message structure that controllers will recognize and use, regardless of the type of networks over which they communicate. It establishes a common format for the layout and contents of message fields, and provides the internal standard that these controllers use for parsing messages.

During communications on this network, the protocol determines how each controller will know its device address, recognize a message addressed to it, determine the kind of action to be taken, and extract any data or other information contained in the message. If a reply is required, the controller will construct the reply message and send it using this protocol.

On other networks, messages containing this protocol are embedded into the frame or packet structure that is used on the network. Modicon network controllers for Modbus Plus or MAP, with associated application software libraries and drivers, provide conversion between the embedded message protocol and the specific framing protocols those networks use to communicate between their node devices. This conversion also extends to resolving node addresses, routing paths, and error-checking methods specific to each kind of network.

At the final point of delivery, however – for example, a controller – the contents of the embedded message, written using this protocol, define the action to be taken. This makes Modicon controllers highly versatile and adaptable to a wide range of industrial automation applications, with the ability to communicate seamlessly over a variety of networks. Contact us today to learn more about our Modicon programmable controllers and how they can benefit your operations.